| Betsie Bay Kayak P.O. Box 1706 Frankfort, MI 49635 Phone: 231-352-7774 Email Us |

| HOME | ||

| Kayaks | ||

| | Recluse | (19') |

| | Manitou | (18') |

| | Aral | (18') |

| | Valkyrie | (17') |

| | Idun | (16') |

| Why B.B.Kayak? | ||

| | History | |

| | Just 27 Pounds?! | |

| | NOT Like A Kit | |

| | Features | |

| Paddles | ||

| Accessories | ||

| Prices & Policies | ||

| FAQs | ||

| Testimonials | ||

| BBK In The News | ||

| Photo Gallery | ||

BETSIE BAY KAYAK

Why a BBK Is NOT Like

A Kit

Current BBK kayaks are produced using a proprietary process unique to the industry. Weve never actually sold a stitch and glue kayak - not once. While kit boats may have the outward appearance of a BBK, the similarity ends there.

For example, our kayaks are molded in special fixtures utilizing infrared heat and vacuum. A BBK is not a plywood boat with fiberglass cloth applied to the outside, like a kit or homebuilt. It is a pressure-molded composite of S-glass and plywood engineered for maximum strength-to-weight ratio.

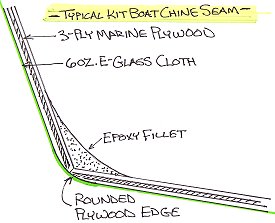

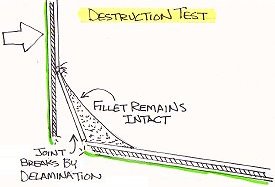

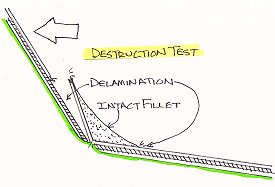

Stitch and glue kayaks have seams where the plywood panels touch and are then rounded off to form the chine. When a stitch and glue seam is broken in destruction testing, it usually fails by the plywood delaminating at the edge. The epoxy fillet holds, but the plywood edge splits:

|

|

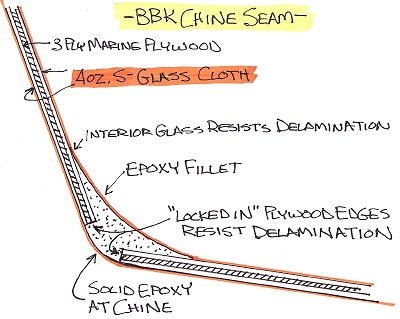

BBK chines are solid epoxy composite. This produces a chine which is much more impact resistant than soft plywood with a thin glass coating:

Our seam locks the plywood edges together for much greater strength. Incidentally, our process allows us a finished seam exterior without sanding the fiberglass. Homebuilders have to sand the fiberglass exterior and tend to take the most off at the chines, where strength is the most critical.

There are many other differences between a BBK and a homebuilt or kit. Weve spent many years optimizing our designs and our construction. A photo of a BBK may look a lot like a photo of a much cheaper kit, just as a photo of a $5000 bicycle looks similar to a photo of a $100 bicycle, in spite of the very real differences.

We feel that our differences represent true value to the BBK owner and allow us to warranty our kayaks.

![]()

|